LMC starts Hydrogen Storage project

In close

cooperation with the R&D department of RSP Technology and the Technical

University of Eindhoven, the LMC will start a feasibility study looking into the

possibilities of the production of Mg-alloys suitable for hydrogen storage for

mobile applications. These alloys will be produced with the meltspinning

technology.

In close

cooperation with the R&D department of RSP Technology and the Technical

University of Eindhoven, the LMC will start a feasibility study looking into the

possibilities of the production of Mg-alloys suitable for hydrogen storage for

mobile applications. These alloys will be produced with the meltspinning

technology.

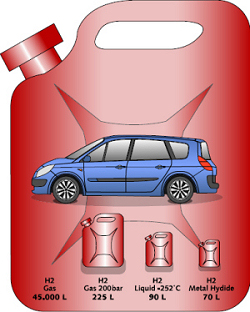

Hydrogen is among the best alternatives to petroleum as an energy

carrier for future applications. It is non polluting and can be produced from

renewable energy sources, like solar- and wind-energy.

The success of a

hydrogen economy depends on the development of safe and cost-effective hydrogen

storage systems (H2 “petrol” tanks). Of the known methods for hydrogen storage

(H2 gas in tank, H2 liquid in tank or H2 as a metal hydride), metal hydrides

offer the best compromise weighing both safety and cost. Metals are capable of

absorbing large amounts of hydrogen, which can be desorbed from the metal at a

later stage when the energy is needed for the fuel cell or the combustion

engine.

For an electric car with a fuel cell on board, about 45,000 litre of

H2 is needed to drive about 400 Km distance. The tank should be the size of a

balloon with a diameter of 5 meters. To put 45,000 litres H2 in a metal Hydride

tank, the size will be that of a normal car (about 70 litres).

In the form of

pressured gas at 200 bar the tank needs to be 225 litre, in a liquid form H2

needs to be cooled down to -252C, the tank size will still be about 90 litre.

Magnesium is an excellent hydrogen storage medium since it can store about 7.7

wt. % hydrogen, more than any other metal or alloy. However, the absorption/desorption

of hydrogen in magnesium is very slow, and a catalyst is needed to accelerate

the reaction. The goal is set to refuel a passenger car in 3-4 minutes. At the

moment a lot of research is done to create the right Mg alloy to be used in

combination with a good production technology. Amorphous Mg-alloys have the best

change, they can be produced by rapid solidification techniques similar to those

present at the LMC.

Part of the feasibility study will be the selection of the

Alloy composition as well as the preferred micro-structure. First results will

be presented before the end of the year.